Polmark – you need to catch up with the best!

With current employment at 340, the company develops its business implementing Industry 4.0 solutions with the support of the Polish Investment Zone programme. The company received the decision to have its new investment supported from the Kraków Technology Park in 2019. Since then it has developed dynamically, catching up with the changes in industry, and simultaneously laying a special emphasis on the development of its staff.

The company operates at two locations: in Wola Rzędzińska, where it produces equipment for electrical installations, and in Żabno, where it produces and sells accessories for pigeon breeding. The latter arm was born from the personal passion of the company’s President, Marek Rzepka, who has long been a famous breeder of homing pigeons in Poland.

The variety of products delivered by POLMARK is impressive, as they range from connectors, via fixed sockets to specialist sockets for computers, aerials, and loudspeakers. The company ships its products from its headquarters situated near Tarnów to all the supermarket chains in Poland, and also exports them to international markets.

However, what counts for the company’s president are not only the new sales markets and technologies. An important, if not the most crucial, aspect is the development of the staff, who are a closely knit, family-like team.

“In POLMARK I have gone through practically all the rungs of the career. While still a student, I worked for the assembly section, looking at how the final product is made. I’ve worked here for nine years, and I’ve gone through the commercial section, client care, and accounting, to become finally the director of production” says Natalia Paw, director of production at POLMARK Tarnów.

Being acquainted with the problems of every section and especially aware of the clients’ needs, Natalia Paw became the champion of modern technological concepts in the company, and is successful in introducing the industrial revolution.

“Thanks to the fact that my mother has worked for the company from the moment it was incorporated, I’ve known how the company prospers and develops from my earliest years. It is thanks to my mum that I could start my career in the company and develop it later”, she commented.

“I believe that POLMARK is our second home, a fact we owe to the way the company is managed, and how you care for people here. Only thanks to the staff, their involvement, and their eagerness to acquire new knowledge, the company is capable of becoming more modern”, she adds.

POLMARK has fine-tuned business needs, strategy, and awareness as to which processes call for optimisation. The company is aware of the studies that say that the companies that will fail to join the digital transformation in the coming seven years will lose their competitive edge in the international markets. Hence the company’s interest in the Polish Investment Zone programme that resulted in the application for a support decision in 2019.

That was the moment when an entirely new approach to production lines started. Its core is unification of product parts to obtain flexible production in result. A profound change of the process of production was designed to increase efficiency and improve product quality. That to a large extent could be achieved thanks to automation and robotisation.

The objective of the further stage of evolution was the digital transformation of the entire value chain and all the assets of the enterprise, including the real-time data exchange connection of equipment and systems.

“It was important to gather together all the fortes of our production. At the moment we use an ERP system that meets most our expectations at work. It is important to use a MES-type system, as it makes it possible for us to analyse the process of production in real-time, which gives the whole management a realistic picture of the situation. The system supports planners by informing them about the degree of completion of production orders. A very important factor is elimination of waste in all the processes that we manage. We opt for optimisation of production regimes by correct management of the resources, standardisation of labour, and unification of parts”, is how the director of production comments on the changes.

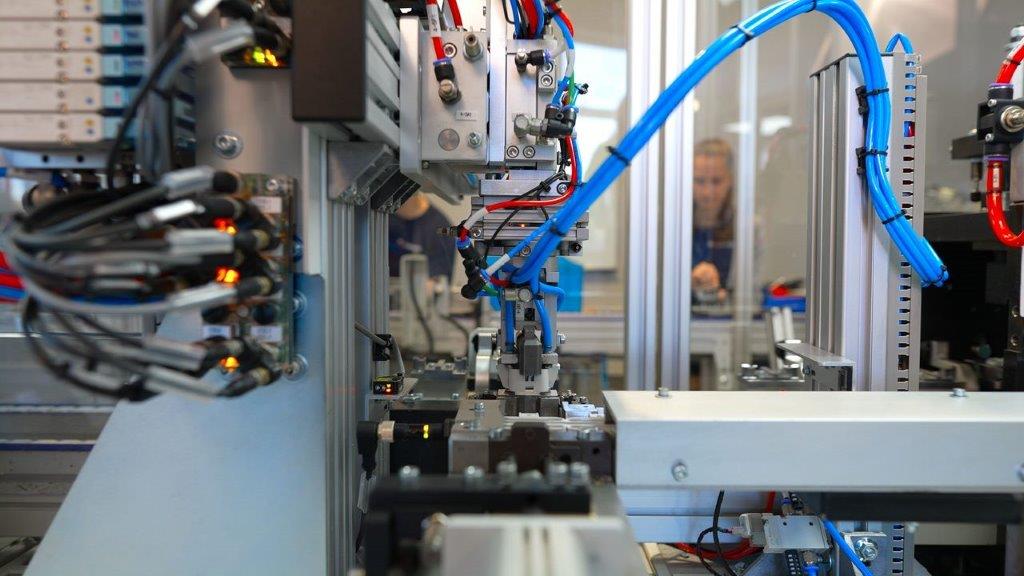

The support decision was delivered to the company on 6 December 2019, and now an investment of PLN 27.5 million will have been completed by the end of 2029 at both the locations. The one in Wola Rzędzińska will receive a new hall, with social and warehouse facilities, production will be aided by modern injection moulding machines and three-axial robots collecting the elements, which will assure the highest quality of the products. The injection moulding plant will be furnished with new material feeding and cooling systems, and heat recuperation installations. The first new robots have already been purchased successfully as part of the strategy for the Investment Zone, and the most important activities are focused on the section for assembly of electric equipment, which will also be automated. The new production lines have been purchased and strongly increased the company’s efficiency. Following the principles of industrial revolution, the production line is flexible and allows for production of the entire range of double sockets.

“Today’s clients are highly demanding, and want to have influence on what they buy. They also usually want to be the designers of their products, at the same time expecting a price corresponding to mass production, which is why we are keen on meeting such expectations”, Natalia Paw says.

The plans include more automatic lines and individual robotised stands so as to reduce the monotony of human labour and speed up the work.

Żabno, in turn, will receive a new-built production hall equipped with the same modern systems. It will produce highest-quality products for pigeon breeders that will now be made with hardly any human labour, as the performance of activities required on these lines is highly monotonous and strenuous for the staff.

“I believe that one of the most important success factors is the development and management of a fantastic team of people, professionals focused on change and pursuit of perfection. Thanks to this, we have obtained fantastic results in the production department and a record increase in the volume of production in the last two years. Everyone in the team develops measurable goals, which are now focused on transformation. We are on a good path to use modern technologies. My greatest personal success is the development of our strategy of transformation and introduction of Industry 4.0 solutions in POLMARK. I will be very happy if we go through this change the way we planned and we will never stop. We want to be the best in the market, and new ideas are already emerging”, Natalia Paw discloses.

POLMARK is a role model for conscious and highly dynamic development towards Industry 4.0. Is worthwhile to learn from the best!

Do you want to learn more about POLMARK Tarnów?

Visit the website: https://www.polmark.pro/

Are you looking for options of support for new investments?

Make yourself acquainted with the Polish Investment Zone (Polska Strefa Inwestycji) programme: https://www.kpt.krakow.pl/polska-strefa-inwestycji/informacje-podstawowe/

Contact

Krakowski Park Technologiczny sp. z o.o.

ul. Podole 60

30-394 Kraków

NIP 675-11-57-834